Tel

86+073187807568

Phone

Phone

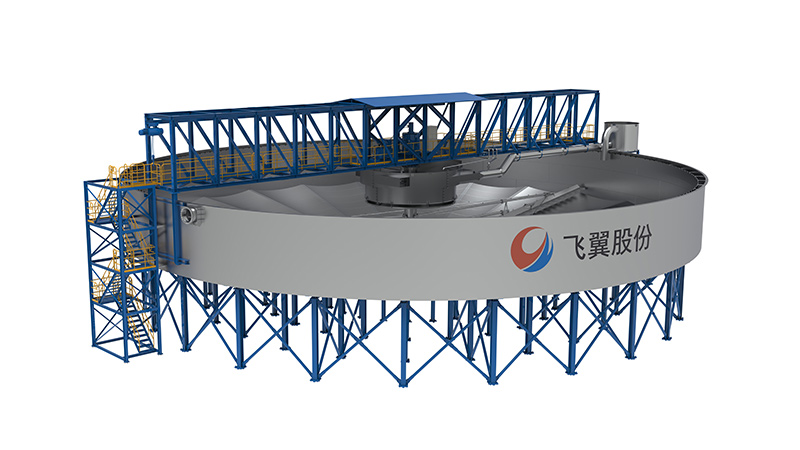

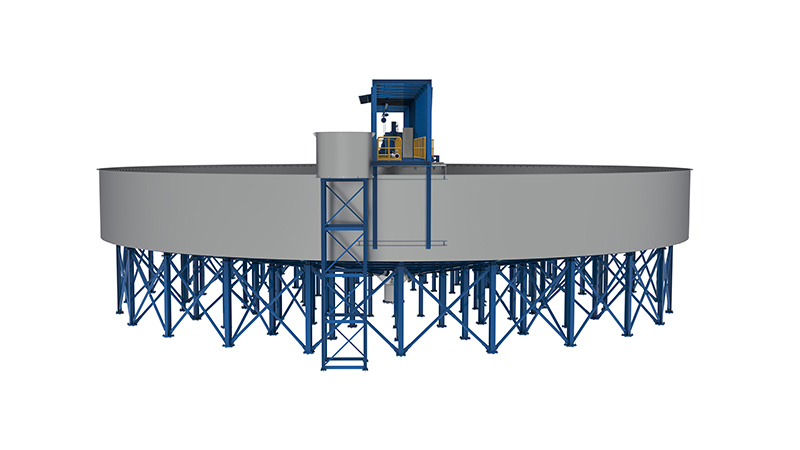

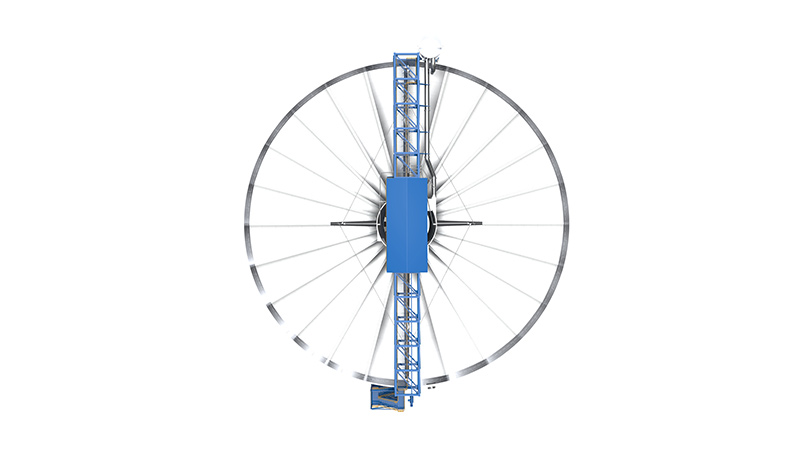

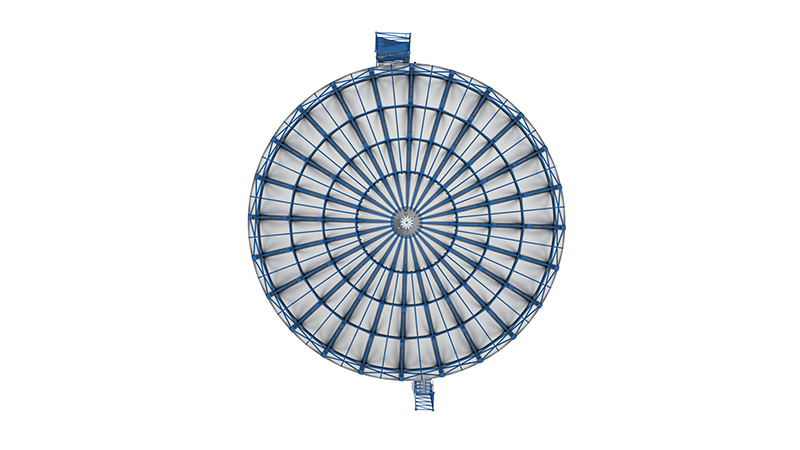

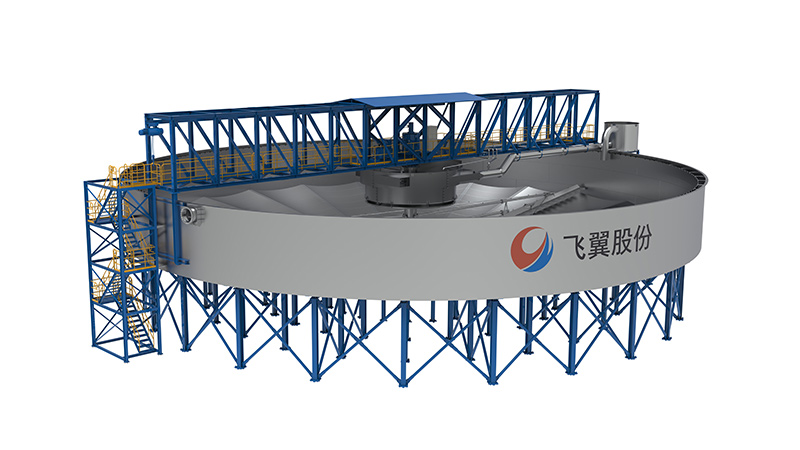

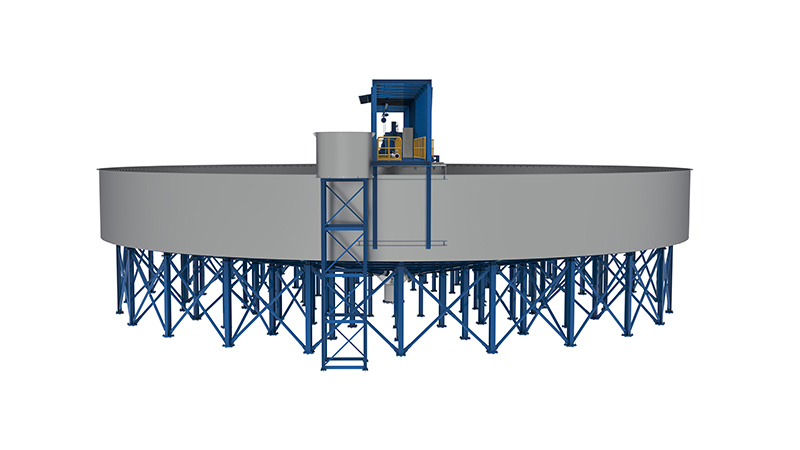

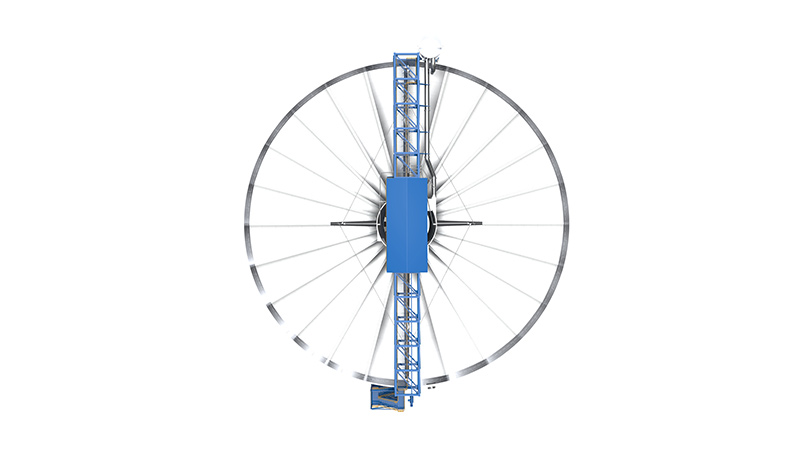

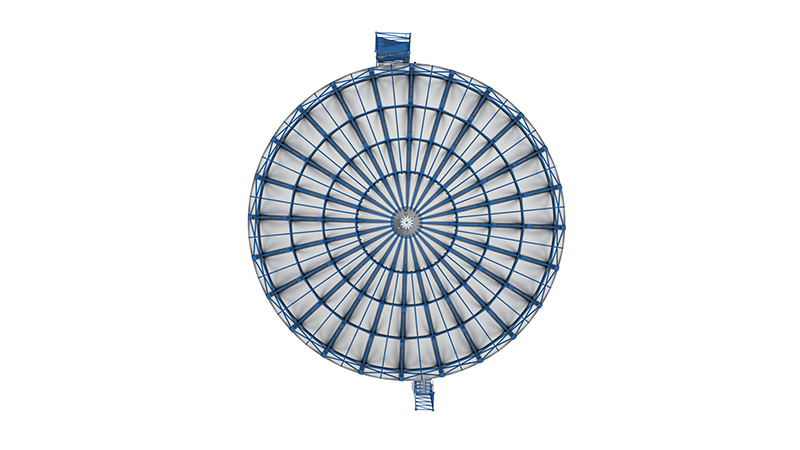

The high-efficiency thickener is primarily used for solid-liquid separation and concentration processes. It is widely applied in mining, metallurgy, chemical processing, and wastewater treatment, effectively enhancing production efficiency and resource utilization.

Efficient feeding high processing capacity low operating costs

|

Model |

NGX09 |

NGX12 |

NGX15 |

NGX18 |

NGX20 |

NGX22 |

NGX25 |

NGX30 |

NGX36 |

NGX38 |

NGX40 |

NGX48 |

|

Inner diameter of thickening tank(m) |

9 |

12 |

15 |

18 |

20 |

22 |

25 |

30 |

36 |

38 |

40 |

48 |

|

Side wall height (m) |

2.2 |

2.4 |

2.4 |

2.4 |

2.4 |

2.4 |

2.6 |

2.8 |

2.8 |

2.8 |

2.8 |

3.2 |

|

Dense bottom taper |

1:4 |

1:5 |

1:6 |

1:6 |

1:6 |

1:6 |

1:6 |

1:6 |

1:6 |

1:6 |

1:6 |

1:6 |

|

Settlement area(㎡) |

63 |

113 |

176 |

254 |

314 |

380 |

490 |

706 |

1017 |

1134 |

1256 |

1808 |

|

Rake end speed(m/min) |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

|

Motor reference power(kW) |

3 |

4 |

5.5 |

7.5 |

7.5 |

7.5 |

11 |

11 |

11 |

15 |

15 |

18.5 |

|

DimensionsL×H(m) |

12.9×9 |

16.3×9.5 |

19.3×9.6 |

22×10 |

22.8×9.8 |

27.7×10 |

28.6×11.3 |

32.8×11.9 |

38.7×12.5 |

41.8×12.9 |

43.7×13.1 |

51.8×15.3 |

|

Processing capacity(t/h) |

10-60 |

20-90 |

30-140 |

40-200 |

50-250 |

60-300 |

75-400 |

100-500 |

150-700 |

180-800 |

200-900 |

250-1250 |

|

Underflow Concentration(%) |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

The high-efficiency thickener is primarily used for solid-liquid separation and concentration processes. It is widely applied in mining, metallurgy, chemical processing, and wastewater treatment, effectively enhancing production efficiency and resource utilization.

|

Model |

NGX09 |

NGX12 |

NGX15 |

NGX18 |

NGX20 |

NGX22 |

NGX25 |

NGX30 |

NGX36 |

NGX38 |

NGX40 |

NGX48 |

|

Inner diameter of thickening tank(m) |

9 |

12 |

15 |

18 |

20 |

22 |

25 |

30 |

36 |

38 |

40 |

48 |

|

Side wall height (m) |

2.2 |

2.4 |

2.4 |

2.4 |

2.4 |

2.4 |

2.6 |

2.8 |

2.8 |

2.8 |

2.8 |

3.2 |

|

Dense bottom taper |

1:4 |

1:5 |

1:6 |

1:6 |

1:6 |

1:6 |

1:6 |

1:6 |

1:6 |

1:6 |

1:6 |

1:6 |

|

Settlement area(㎡) |

63 |

113 |

176 |

254 |

314 |

380 |

490 |

706 |

1017 |

1134 |

1256 |

1808 |

|

Rake end speed(m/min) |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

8-12.5 |

|

Motor reference power(kW) |

3 |

4 |

5.5 |

7.5 |

7.5 |

7.5 |

11 |

11 |

11 |

15 |

15 |

18.5 |

|

DimensionsL×H(m) |

12.9×9 |

16.3×9.5 |

19.3×9.6 |

22×10 |

22.8×9.8 |

27.7×10 |

28.6×11.3 |

32.8×11.9 |

38.7×12.5 |

41.8×12.9 |

43.7×13.1 |

51.8×15.3 |

|

Processing capacity(t/h) |

10-60 |

20-90 |

30-140 |

40-200 |

50-250 |

60-300 |

75-400 |

100-500 |

150-700 |

180-800 |

200-900 |

250-1250 |

|

Underflow Concentration(%) |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

45-55 |

Scan code attention