Tel

86+073187807568

Phone

Phone

Scientific

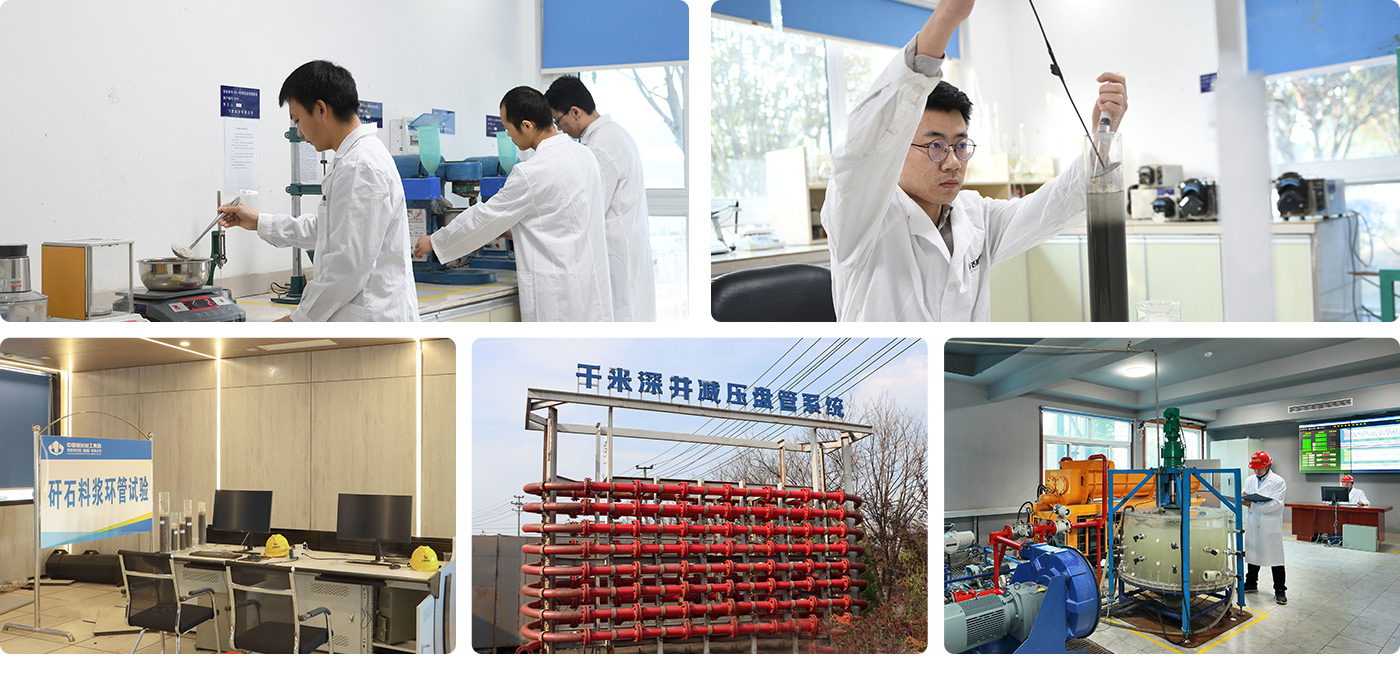

Research and Experimentation Platforms

FENY Co.,Ltd.has established several scientific platforms,including the"National Energy Backfill Mining Technology Key Laboratory FENY Workstation,"the Hunan Province Mine Backfill Equipment Engineering Technology Research Center,the Hunan Province Academician Expert Workstation,and the Hunan Province Enterprise Technology Center.It is also an important member of the"Key Laboratory for Safe and Green Mining of Metal Paste Backfill"under the Chinese National Mine Safety Administration.

The company boasts a strong and innovative technical R&D team with nearly 300 members,including 10 PhDs and over 40 master's degree holders.The team includes seven R&D departments:Backfill Engineering Design Institute,Backfill Product Design Institute,Information and Intelligent Control Design Institute,Backfill Materials Research Institute,Backfill Laboratory,Process Equipment Department,and Hydraulic-Electric Comprehensive Laboratory.These departments are responsible for designing backfill solutions,developing complete sets of backfill equipment,researching intelligent backfill technology,developing new backfill materials,conducting semi-industrial backfill tests,designing manufacturing processes for backfill equipment,and commissioning and testing backfill systems.Their efforts ensure seamless integration of all subsystems in the backfill process,providing users with"stable,efficient,reliable,and intelligent"backfill system technologies and complete high-end equipment.

Backfill Design Center:

The FENY Mine Backfill Engineering Design Institute is dedicated to innovating mining backfill technology. It customizes personalized and cost-effective backfill system processes and overall solutions for users, considering their specific operating conditions and conducting backfill experiments. The FENY Backfill Product Design Institute focuses on developing new backfill equipment and improving existing technologies. It has independently developed a range of high-performance mining equipment, including large industrial backfill pumps, deep-cone high-efficiency thickeners, horizontal double-shaft mixers, vertical high-power stirring tanks, mining concrete pumps, and mining warehouse cleaning machines, ensuring reliable high-end equipment support for backfill technology.

The FENY Information and Intelligent Control Institute focuses on in-depth research into intelligent backfill control systems and informatization. The institute's intelligent control system consists of one central system and six key subsystems, including a data center, one-click backfill control system, 3D data twin system, intelligent reporting system, production management system, underground monitoring system, and video surveillance system. This system integrates cutting-edge technologies such as big data analytic, IoT, and AI, enabling comprehensive automation in monitoring and controlling backfill production. Through precise data analysis and intelligent decision-making support, the system can automatically adjust backfill parameters, ensuring high efficiency and safety in backfill operations, significantly enhancing the level of automation in backfill production.

The FENY Process Equipment Department is responsible for the process design of all products developed by the three design institutes, overseeing the entire process from blueprint review, work time assessment, tooling design, packaging and transportation, industrial design and color matching, to process planning and evaluation. The department aims to enhance production efficiency and reduce manufacturing costs using advanced and rational processes. It also manages the procurement, maintenance, and management of production equipment and oversees the production workshop layout, engineering construction, plant renovation, and technical improvements.

Backfill Materials Experimental Center

The FENY New Materials Research Institute is committed to developing environmentally friendly new backfill materials. These new paste materials primarily use industrial waste from power plants, coal chemical plants, and smelters as the main raw materials, with over 90% of the binding material comprising these waste materials. The production process is simple and cost-effective, enabling comprehensive utilization of solid waste. The materials are characterized by their ability to "treat waste with waste," non-burning, non-discharge, wide applicability, and cost-effectiveness. The institute has independently developed various new materials, including soil stabilizers, slag-based binders, metal smelting slag-based binders, and coal-based binders. These materials can completely replace cement, addressing challenges such as ultra-fine tailings, special tailings, low early strength in coal mine backfill, and high binder usage costs. The institute also owns a factory with an annual production capacity of over 200,000 tons of new binding materials.

FENY has an advanced paste backfill experimental research laboratory that conducts a series of experimental studies, including physicochemical property analysis, flocculation sedimentation experiments, mix ratio experiments, loop experiments, and semi-industrial thickening experiments. These experiments provide strong foundational support for the design, construction, and operation of backfill systems.

Hydraulic-Electric Control Comprehensive Laboratory

The Hydraulic-Electric Control Comprehensive Laboratory can test the performance ofhydraulic systems in piston-type industrial pumps and thickeners, measuring pressure losses in pumps, valves, cylinders, and pipelines under different flow conditions. This ensures the efficient operation of hydraulic systems with low energy consumption. The laboratory also provides critical data for the development of intelligent equipment by simulating real experimental conditions.

The laboratory can conduct real-time online monitoring of the entire process flow and equipment operation, establish intelligent analysis models, and optimize models, offering full-line database support. It has created an expert knowledge base at FENY to provide remote diagnostics and analysis of equipment failures. The laboratory records system operation time and backfill volume in real-time, calculating time and volume to provide early warnings to customers, helping them plan equipment maintenance in advance. Before equipment leaves the factory, it undergoes simulated operation testing in the experimental platform under actual working conditions, significantly reducing on-site commissioning time, minimizing failure rates, and improving the success rate and economic efficiency of equipment commissioning.

Here is the translation of the provided standards:

1. **GB/T 39988-2021** - "Technical Specifications for Preparation and Storage of Full Tailings Paste" of the People's Republic of China.

2. **GB/T 39489-2020** - "Technical Specifications for Full Tailings Paste Backfill" of the People's Republic of China.

3. **GB/T 51450-2022** - "Technical Standards for Backfill Engineering in Metal and Non-Metal Mines" of the People's Republic of China.

4. **JB/T 13439-2018** - "Piston-Type Backfill Pump for Mining" (Machinery Industry Standard) of the People's Republic of China.

5. **T/CAEPI 32-2021** - "Technical Requirements for Key Equipment in Full Tailings Paste Backfill" (Group Standard).

Scan code attention