Tel

86+073187807568

Phone

Phone

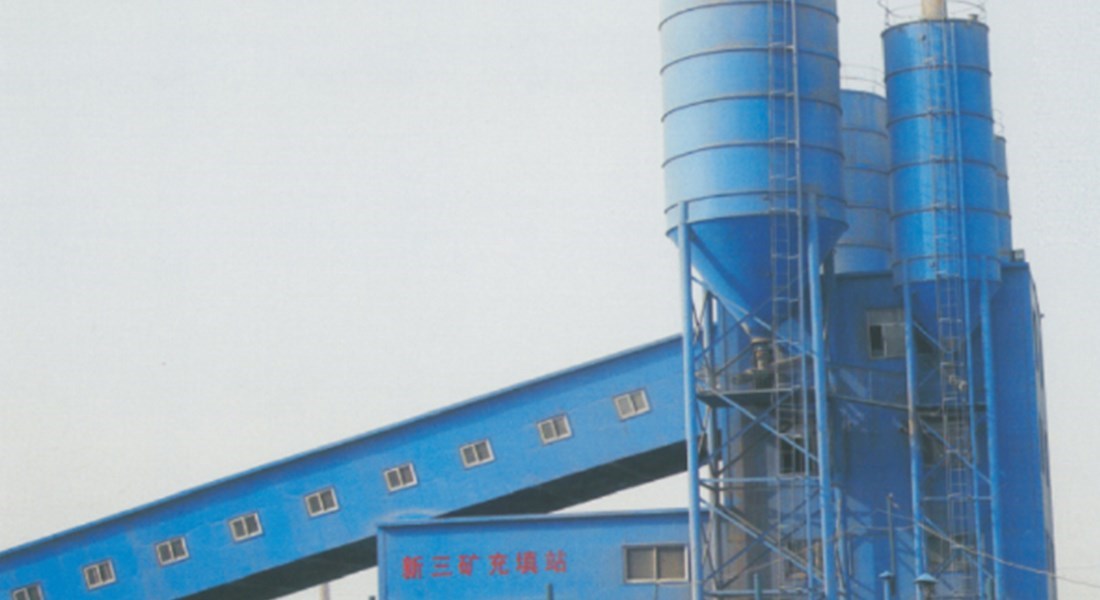

The project involves a thorough study of the characteristics of mined-out areas in the Shangwan and Bulianta coal mines. It employs a series of processes including crushing, ball milling,slurry preparation, paste preparation, intelligent sorting of gangue,and intelligent control..

Through the three-stage crushing process of "counterattack breaking + high-fine breaking + vertical shaft impact breaking", the coal gangue is prepared into the reasonable grading grouting material of -3mm.

After crushing and screening, coal gangue is used as the main filling aggregate, and fly ash and cement are added at the same time. The filling system capacity is 200m³/h, and the annual filling and mining capacity reaches 600,000 tons.

Zisheng coal mine uses gangue + cement + fly ash + water for paste backfill. Backfill system capacity 150m3 /h, conveying distance up to 2500 meters.

Using the coal gangue paste backfill process, the system innovatively employs a dual-pump merging technique, with a backfill system capacity of 160 m³/h.

The filling system capacity is 160m³/h by using the coal gangue paste filling process and the innovative combined flow process with double pumps.

The designed filling and mining capacity is 1.2 million t/a, the coal gangue paste filling process is adopted, and the system capacity is 460m³/h.The design backfill mining capacity is 1.2 million tons per year, using the coal gangue paste backfill process, with a system capacit..

Coal gangue is used as the main backfill aggregate after crushing,and is mixed with fly ash,cement,and additives.The backfill system has a capacity of 250 m³/h,with an annual backfill volume reaching 1.2 million tons.Project results:the first paste filling system in China to rea..

The filling station adopts HGBS160.15.710 type filling industrial pump produced by Feiyi Company. Using construction waste as the main filling material, the paste strip filling mining is completed.

Using FENY's paste backfill system, several key technologies, including simultaneous mining and backfilling, have been achieved.

Xiaoma Coal Mine uses FENY HGBS200.14.800 backfill pump for coal extraction and backfilling under villages. A surface station is established to pump the slurry to underground mined-out areas.The transport distance includes 30 meters of horizontal pipe, 120meters of vertical pipe..

Liudong Coal Mine has a serious issue with coal seams trapped beneath buildings, water bodies, and railways (or highways), with a coal volume of 24.892 million tons affected. Using the 5,000-meter single-stage pumping system developed by FENY, t

Scan code attention