Tel

86+073187807568

Phone

Phone

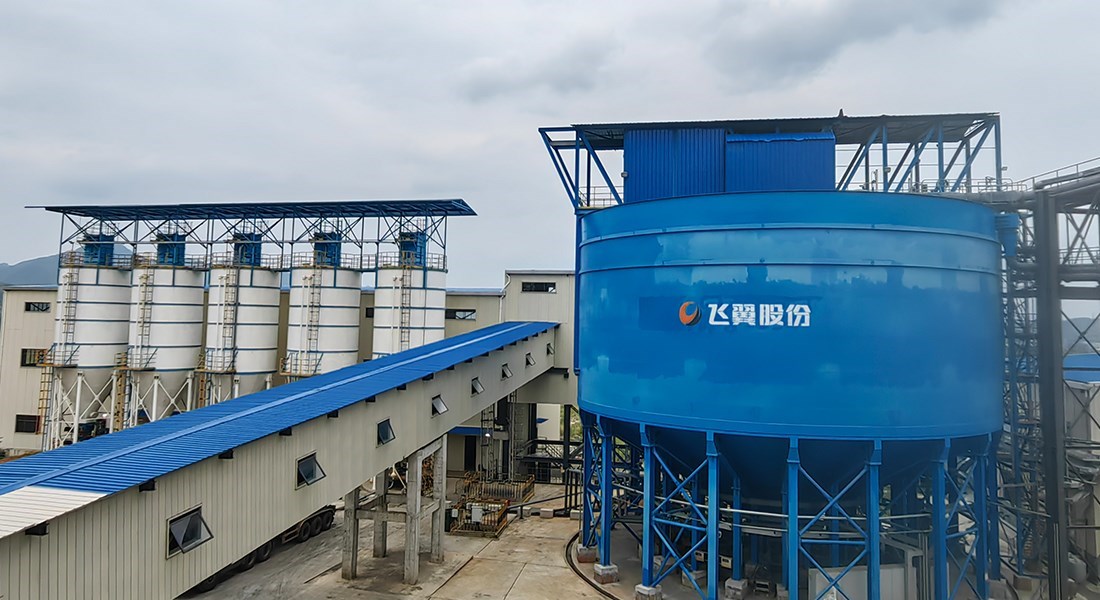

The vertical sand silo is used to concentrate and settle all tailings, and the filling mass concentration is 66%-70%. The total capacity of the filling system is 540m³/h (four sets of systems, three uses and one standby).

The deep cone thickener (NGT16) was used to concentrate and settle all tailings pulp, the filling mass concentration was 70% ~ 72%, and the system filling capacity was 100m³/h.

The deep cone thickener (NGT22) was used to concentrate and settle all tailings pulp, the filling mass concentration was 66%-70%, and the system filling capacity was 150m³/h.

Using full tailings and waste rock as filling aggregates, the filling slurry concentration is 77% to 79%, with a 28-day strength greater than 5 MPa. The capacity of a single system is 100 m³/h, with an annual filling volume exceeding 500,000 m³.

The project uses cyclones for pre-classification of concentration tailings, separating coarse and fine tailings for different treatments. The coarse tailings are filtered to produce filter cakes, while the fine tailings are thickened through a thickener, ensuring the stability o..

The first full tailings paste backfill project in Hunan Province, uses a one-stage deep cone thickener process, combined with new cementitious materials independently developed by FENY.

Use the full tailings paste backfill process , with the filling station utilizing two deep cone thickeners, each with an meter diameter, and three sets of mixing and pumping systems (one set as backup). Each system has a capacity of 120 m³/h, total filling capacity of 360 m³/h.

For the high-altitude, high-concentration, and high-drop working conditions at the Yalong River Mine, FENY independently developed the HGBZ70.15.320G cone valve industrial pump. Through the use of large-diameter sliding valve parallel synchronous control and high-flow, high-back..

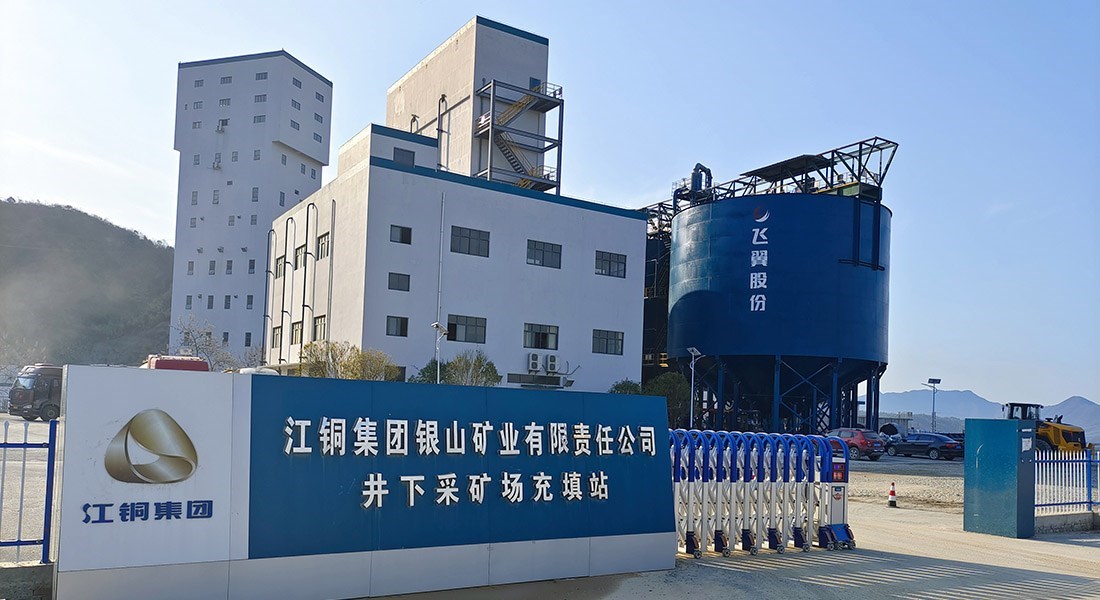

The designed mining methods mainly include the stage stopping followed by backfill method, and the upward stratified backfill method. The backfill station primarily consists of deep cone thickeners, cement silos, and mixing systems.

Phosphogypsum dihydrate, phosphogypsum semihydrate, phosphogypsum tailing and modifier are used as filling aggregate, the system filling capacity is 120m³/h, and the filling mass concentration is 70%.

The filling capacity of the system is 100m³/h, the slurry is thickened to 73% through the deep cone paste thickener, and the filling slurry is prepared by adding cement, and the conveying distance can reach 2000 meters.

The tailings are pre-classified at the processing plant, with coarse particle size tailings entering the vertical sand silo and overflow tailings entering the deep cone thickener. This fundamentally addresses safety hazards in mined-out areas and, through backfill, maximizes the..

Scan code attention