Tel

86+073187807568

Phone

Phone

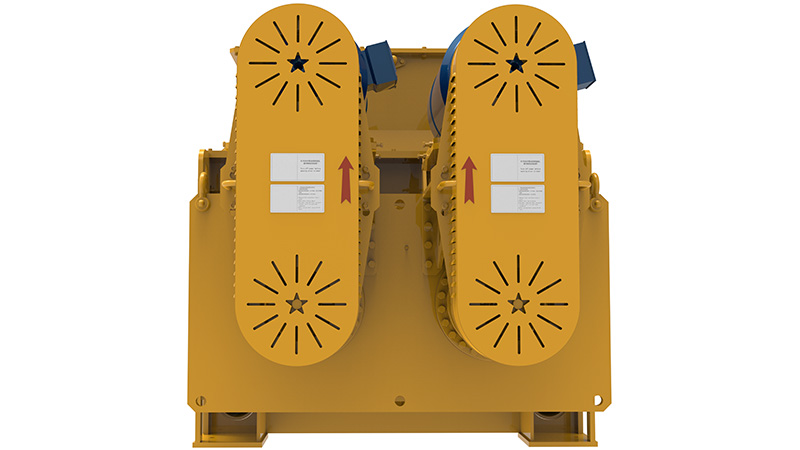

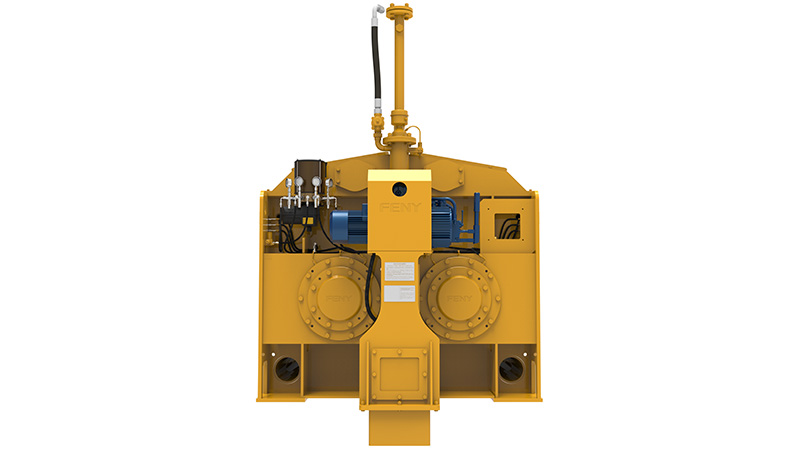

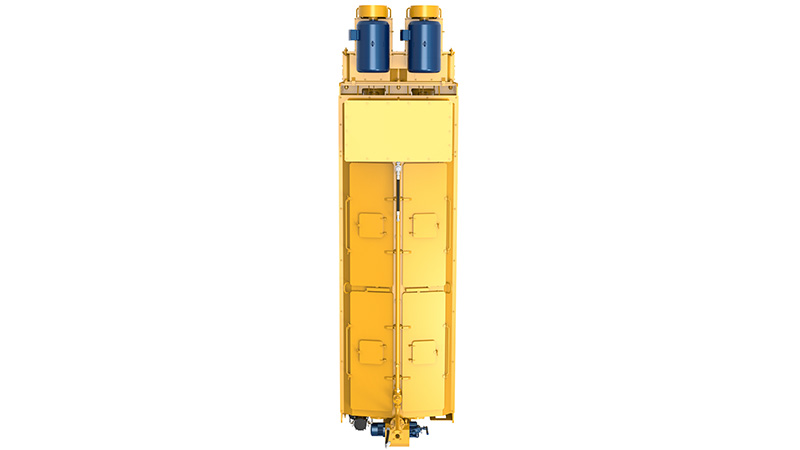

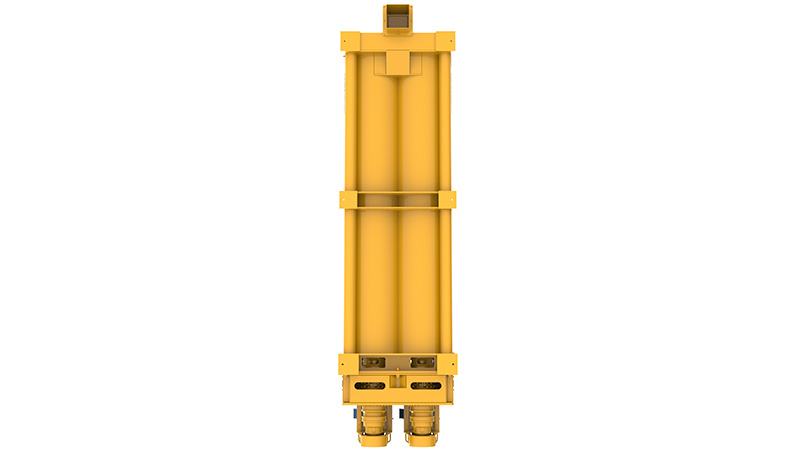

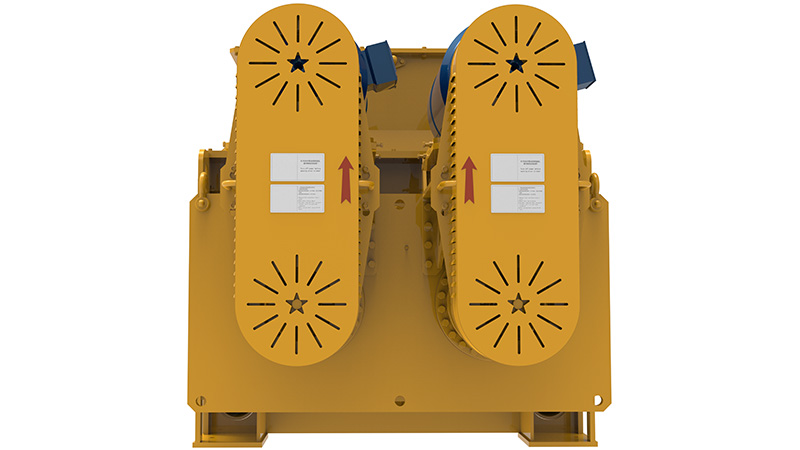

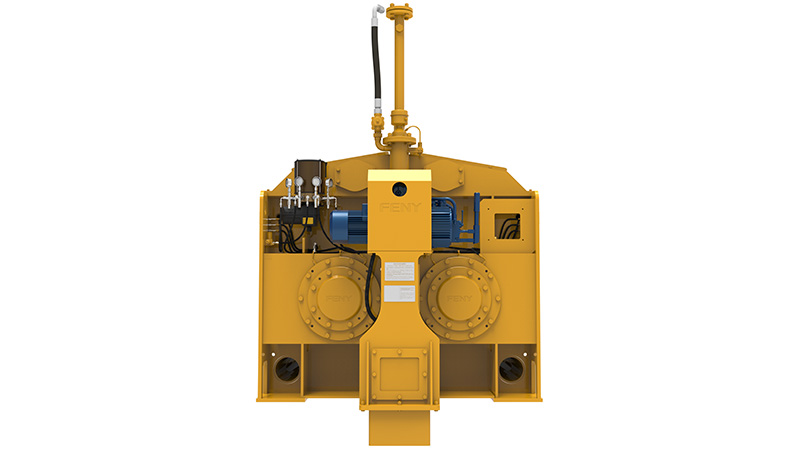

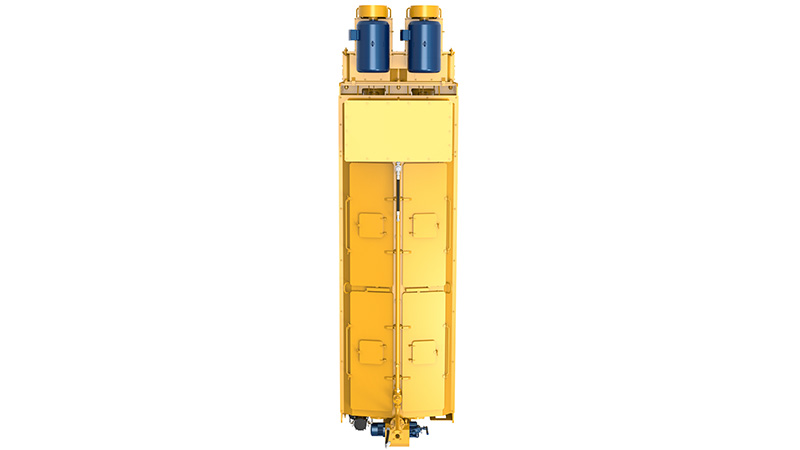

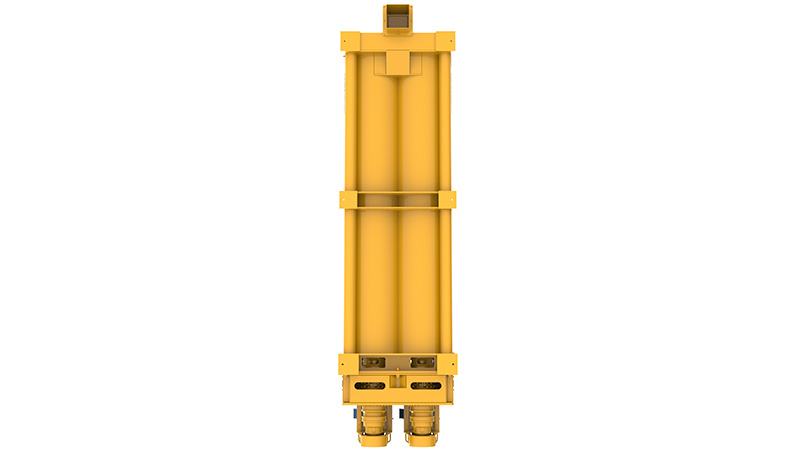

This equipment is the core product of paste mixing system, it is a high efficient mixer, especially suitable for handling coarse aggregate mixture. It is mainly used in high concentration tailing backfill system, and also can be used in construction, public (railway) road, bridge and other industries.

Stable performance Large mixing volume Good mixing effect Continuous feeding and discharging low noise easy maintenance

● Excellent mixing effect:

The mixing arms and blades undergo relative reverse rotation of the two staggered mixing shafts to ensure that the material generates violent mixing movement in the vertical and horizontal directions,forming a forced meandering mixing and feeding.

● High-efficiency sealing:

Adopting floating oil sealing ring and special seals with pressure grease to form a multi-layer labyrinth sealing structure,with better sealing effect.It effectively solves the technical problem of slurry leakage at the shaft end which is common in the industry.

|

Project |

Parameter |

|||||||

|

Mixing materials |

Mineral mixtures, cement-stabilized gravel base concrete, backfill sealants, concrete, dry mixtures, etc |

|||||||

|

Solids content |

50%~85% |

|||||||

|

Slump(cm) |

20~28 |

|||||||

|

Model |

JSL4000 |

JSL6000 |

JSL8000 |

JSL1000 |

JSL12000 |

JSL14000 |

JSL16000 |

JSL18000 |

|

Theoretical yield(m3/h) |

120 |

180 |

240 |

300 |

360 |

420 |

480 |

540 |

|

Rotate speed(rpm) |

53 |

47 |

42 |

42 |

37 |

37 |

37 |

37 |

|

Stirring circle diameter(mm) |

740 |

840 |

980 |

1100 |

1240 |

1300 |

1360 |

1440 |

|

Blend segment length(mm) |

4000 |

4270 |

4480 |

4490 |

4720 |

4850 |

5000 |

5000 |

|

Maximum aggregate particle size(mm) |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

|

Motor power(kW) |

2×30 |

2×45 |

2×55 |

2×75 |

2×90 |

2×110 |

2×132 |

2×160 |

|

Noltage(V) |

380/660 |

|||||||

|

Quality(t) |

≈8 |

≈10 |

≈11 |

≈12 |

≈15 |

≈18 |

≈21 |

≈24.5 |

All of the above manuals apply to standard specifications.

The technical parameters of the customer-specific specifications may deviate from the data in the table above.

All technical parameters will be updated according to the research and development situation, and our company reserves the right to change at any time.

This equipment is the core product of paste mixing system, it is a high efficient mixer, especially suitable for handling coarse aggregate mixture. It is mainly used in high concentration tailing backfill system, and also can be used in construction, public (railway) road, bridge and other industries.

● Excellent mixing effect:

The mixing arms and blades undergo relative reverse rotation of the two staggered mixing shafts to ensure that the material generates violent mixing movement in the vertical and horizontal directions,forming a forced meandering mixing and feeding.

● High-efficiency sealing:

Adopting floating oil sealing ring and special seals with pressure grease to form a multi-layer labyrinth sealing structure,with better sealing effect.It effectively solves the technical problem of slurry leakage at the shaft end which is common in the industry.

|

Project |

Parameter |

|||||||

|

Mixing materials |

Mineral mixtures, cement-stabilized gravel base concrete, backfill sealants, concrete, dry mixtures, etc |

|||||||

|

Solids content |

50%~85% |

|||||||

|

Slump(cm) |

20~28 |

|||||||

|

Model |

JSL4000 |

JSL6000 |

JSL8000 |

JSL1000 |

JSL12000 |

JSL14000 |

JSL16000 |

JSL18000 |

|

Theoretical yield(m3/h) |

120 |

180 |

240 |

300 |

360 |

420 |

480 |

540 |

|

Rotate speed(rpm) |

53 |

47 |

42 |

42 |

37 |

37 |

37 |

37 |

|

Stirring circle diameter(mm) |

740 |

840 |

980 |

1100 |

1240 |

1300 |

1360 |

1440 |

|

Blend segment length(mm) |

4000 |

4270 |

4480 |

4490 |

4720 |

4850 |

5000 |

5000 |

|

Maximum aggregate particle size(mm) |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

|

Motor power(kW) |

2×30 |

2×45 |

2×55 |

2×75 |

2×90 |

2×110 |

2×132 |

2×160 |

|

Noltage(V) |

380/660 |

|||||||

|

Quality(t) |

≈8 |

≈10 |

≈11 |

≈12 |

≈15 |

≈18 |

≈21 |

≈24.5 |

All of the above manuals apply to standard specifications.

The technical parameters of the customer-specific specifications may deviate from the data in the table above.

All technical parameters will be updated according to the research and development situation, and our company reserves the right to change at any time.

Scan code attention