Tel

86+073187807568

Phone

Phone

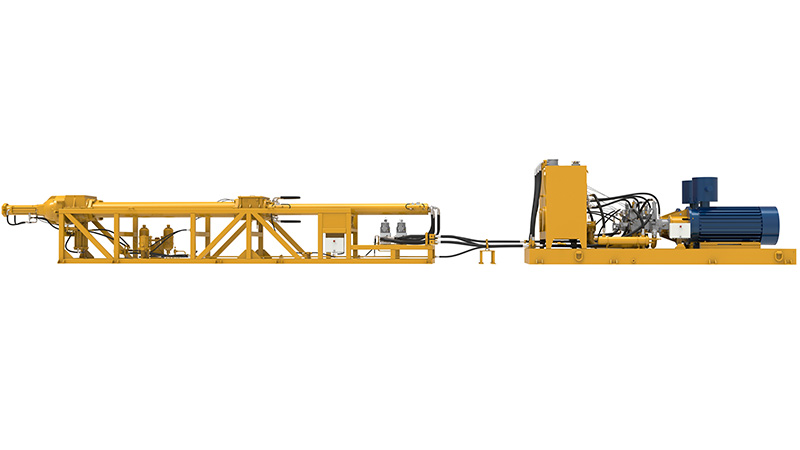

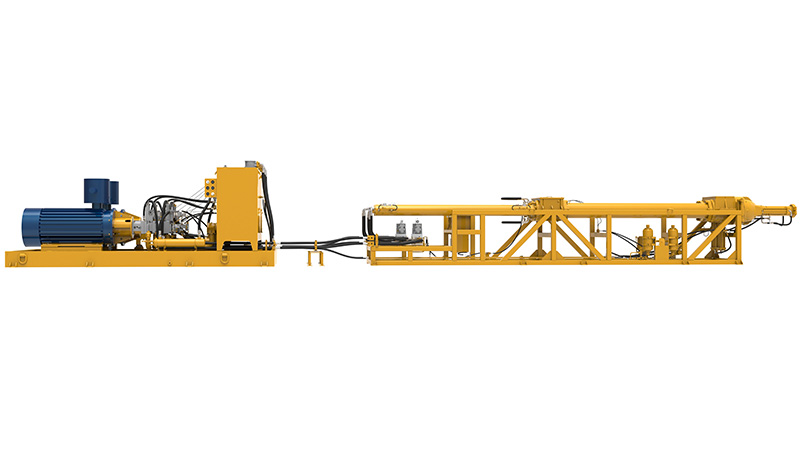

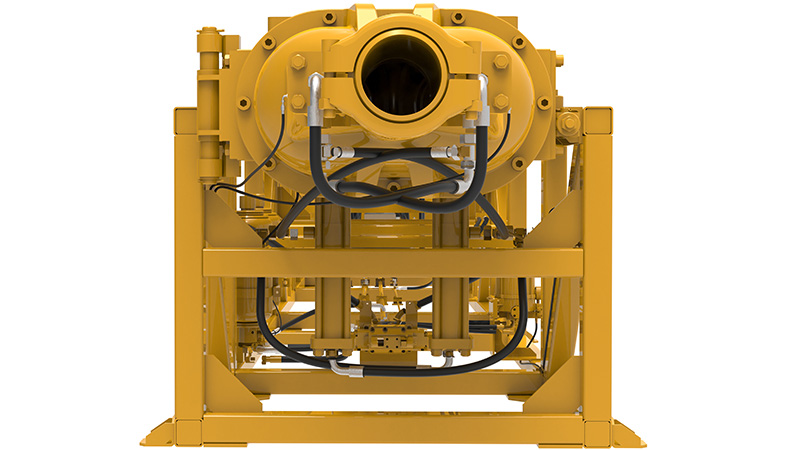

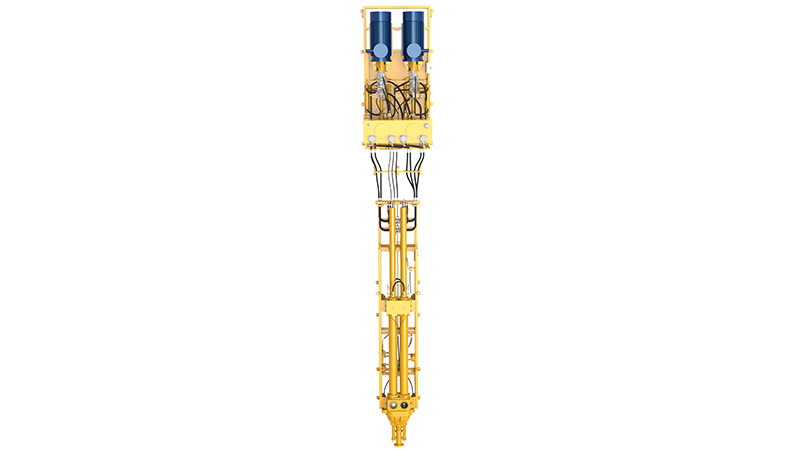

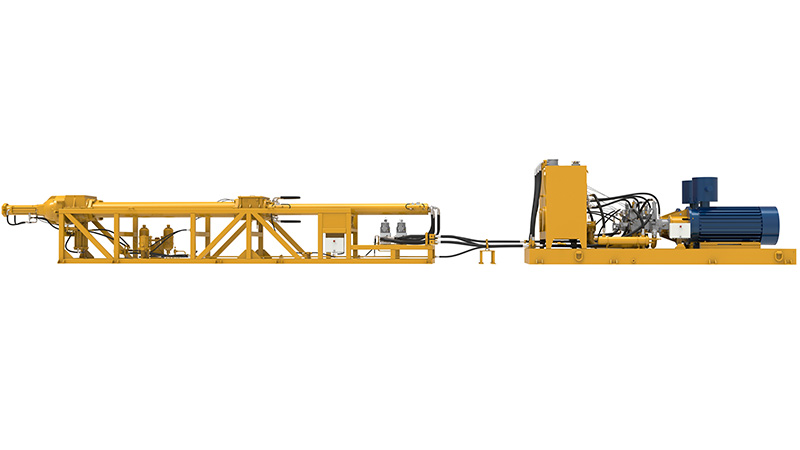

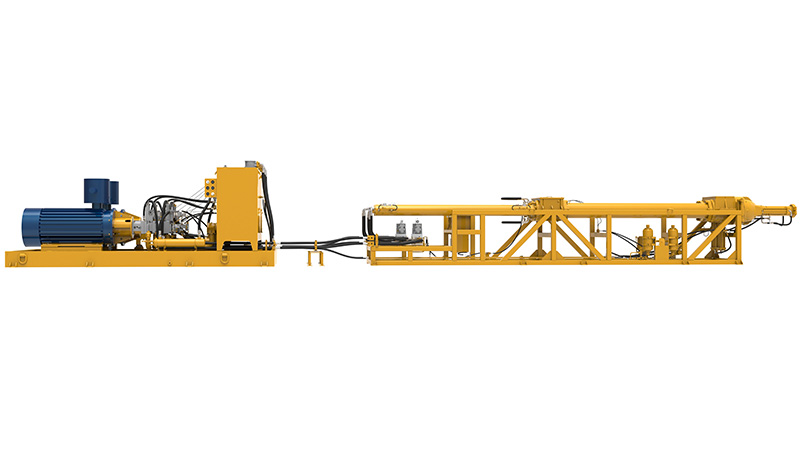

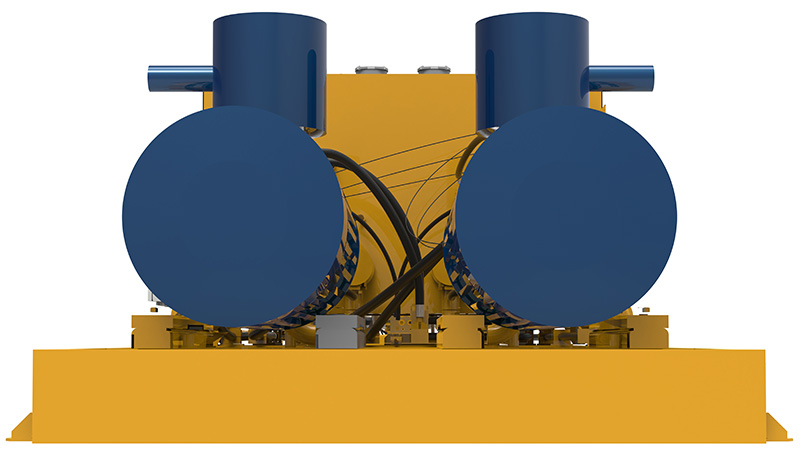

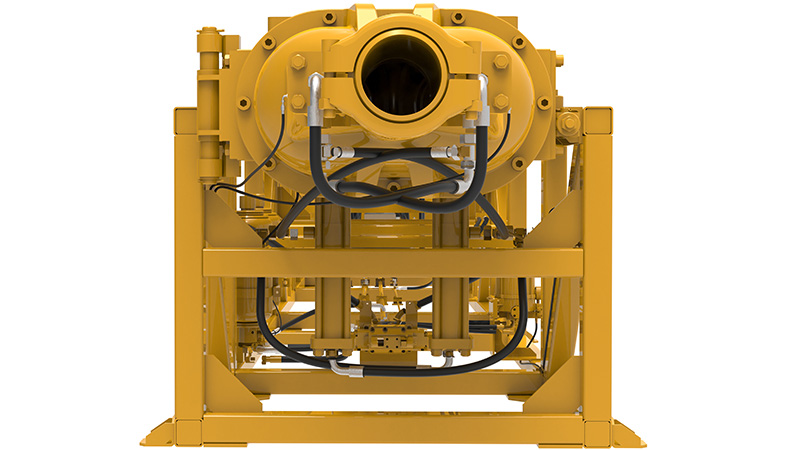

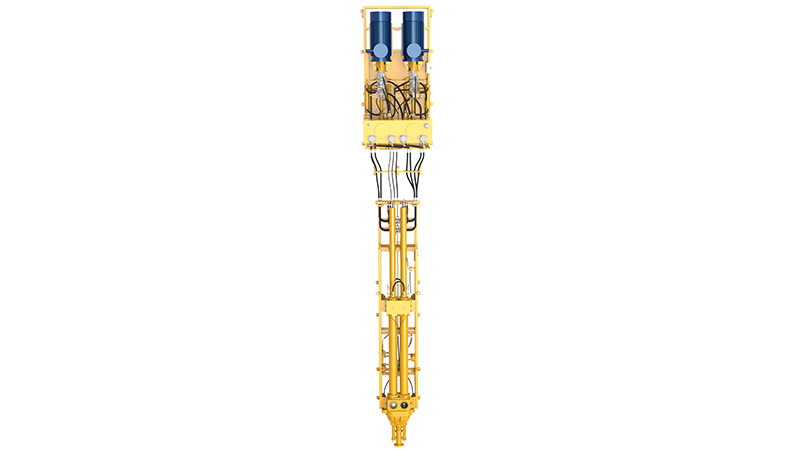

This equipment is the core product of paste backfill and pumping system, which is widely used in the fields of paste backfill in metal mines, high concentration discharge of tailings, sewage treatment in metallurgy and petrochemical industries,and solid waste treatment, and it provides safe and reliable long-distance conveying equipment for high solid content and viscous fine-grained materials with complex composition. It adopts unique conical distribution valve with good sealing and long life of wearing parts. The maximum outlet pressure is up to 21MPa, and the maximum conveying capacity is 500m³/h.

various of utilization large volume The conveying distance is long long-distance transportation high reliability high safety level

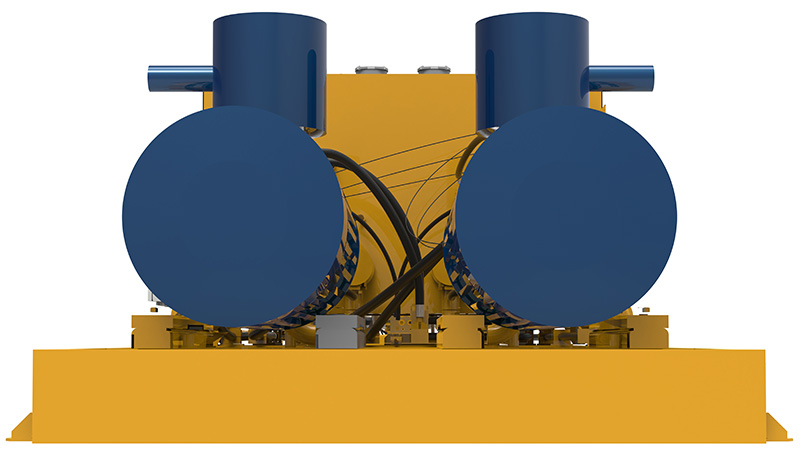

Adopting full electric control reversing technology and imported hydraulic components,dual power hydraulic station,working in parallel,independent of each other,and standby for each other.

|

Project |

Parameter |

|||||

|

Pumping materials |

Fly ash paste, tailings paste, red mud, sludge, coal slime, etc |

|||||

|

Solids content |

50%~85% |

|||||

|

Maximum material particle size(mm) |

5 |

|||||

|

Slump(cm) |

20~28 |

|||||

|

Model |

HGBZ70.10.220 |

HGBZ90.10.320 |

HGBZ110.10.400 |

HGBZQ150.12.630 |

HGBZW320.12.1800 |

HGBZ500.16.3200 |

|

Maximum theoretical outlet displacement(m3/h) |

68.5 |

92 |

110 |

150 |

323.3 |

500 |

|

Maximum continuous working pressure(MPa) |

10 |

10 |

10 |

12 |

12 |

16 |

|

Inner diameter of the conveying cylinder(mm) |

Φ300 |

Φ300 |

Φ300 |

Φ300 |

Φ460 |

Φ560 |

|

Conveyor cylinder stroke(mm) |

2100 |

2100 |

2500 |

3100 |

3100 |

3500 |

|

Motor power(kW) |

220 |

320 |

400 |

630 |

1800 |

3200 |

|

Voltage(V) |

380 |

380 |

380 |

6k |

10k |

10k |

|

Poppet valve piston pump dimensions G×H×I(mm) |

7510×1750×1481 |

7510×1750×1481 |

8310×1750×1481 |

9490×1750×1481 |

12171×2360×2459 |

12900×2750×2340 |

|

Hydraulic power pack dimensions D×E×F(mm) |

4100×2062×2195 |

4100×2062×2195 |

4250×2750×2195 |

4200×2750×2195 |

6800×2980×2463 |

8520×3410×4250 |

|

Poppet valve piston pump quality(kg) |

约6430 |

约6700 |

约7500 |

约7442 |

约22000 |

约42000 |

|

Hydraulic power pack quality(kg) |

约4160 |

约6000 |

约6000 |

约10178 |

约16000 |

约41650 |

This equipment is the core product of paste backfill and pumping system, which is widely used in the fields of paste backfill in metal mines, high concentration discharge of tailings, sewage treatment in metallurgy and petrochemical industries, and solid waste treatment, and it provides safe and reliable long-distance conveying equipment for high solid content and viscous fine-grained materials with complex composition. It adopts unique conical distribution valve with good sealing and long life of wearing parts. The maximum outlet pressure is up to 21MPa, and the maximum conveying capacity is 500m³/h.

Adopting full electric control reversing technology and imported hydraulic components,dual power hydraulic station,working in parallel,independent of each other,and standby for each other.

|

Project |

Parameter |

|||||

|

Pumping materials |

Fly ash paste, tailings paste, red mud, sludge, coal slime, etc |

|||||

|

Solids content |

50%~85% |

|||||

|

Maximum material particle size(mm) |

5 |

|||||

|

Slump(cm) |

20~28 |

|||||

|

Model |

HGBZ70.10.220 |

HGBZ90.10.320 |

HGBZ110.10.400 |

HGBZQ150.12.630 |

HGBZW320.12.1800 |

HGBZ500.16.3200 |

|

Maximum theoretical outlet displacement(m3/h) |

68.5 |

92 |

110 |

150 |

323.3 |

500 |

|

Maximum continuous working pressure(MPa) |

10 |

10 |

10 |

12 |

12 |

16 |

|

Inner diameter of the conveying cylinder(mm) |

Φ300 |

Φ300 |

Φ300 |

Φ300 |

Φ460 |

Φ560 |

|

Conveyor cylinder stroke(mm) |

2100 |

2100 |

2500 |

3100 |

3100 |

3500 |

|

Motor power(kW) |

220 |

320 |

400 |

630 |

1800 |

3200 |

|

Voltage(V) |

380 |

380 |

380 |

6k |

10k |

10k |

|

Poppet valve piston pump dimensions G×H×I(mm) |

7510×1750×1481 |

7510×1750×1481 |

8310×1750×1481 |

9490×1750×1481 |

12171×2360×2459 |

12900×2750×2340 |

|

Hydraulic power pack dimensions D×E×F(mm) |

4100×2062×2195 |

4100×2062×2195 |

4250×2750×2195 |

4200×2750×2195 |

6800×2980×2463 |

8520×3410×4250 |

|

Poppet valve piston pump quality(kg) |

约6430 |

约6700 |

约7500 |

约7442 |

约22000 |

约42000 |

|

Hydraulic power pack quality(kg) |

约4160 |

约6000 |

约6000 |

约10178 |

约16000 |

约41650 |

Scan code attention