Tel

86+073187807568

Phone

Phone

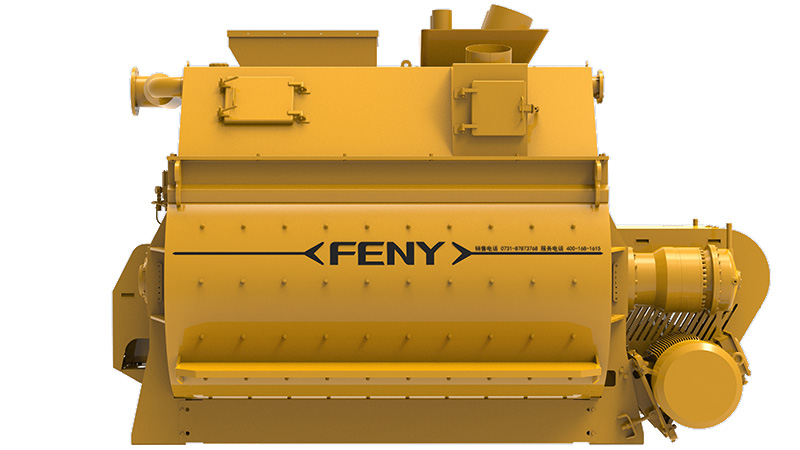

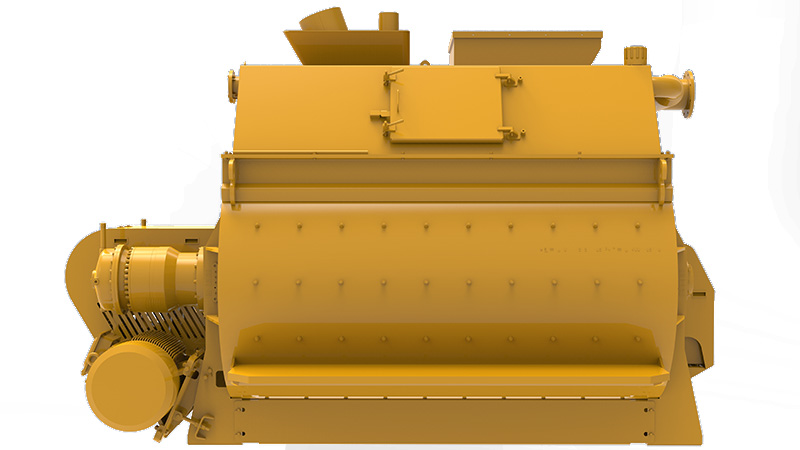

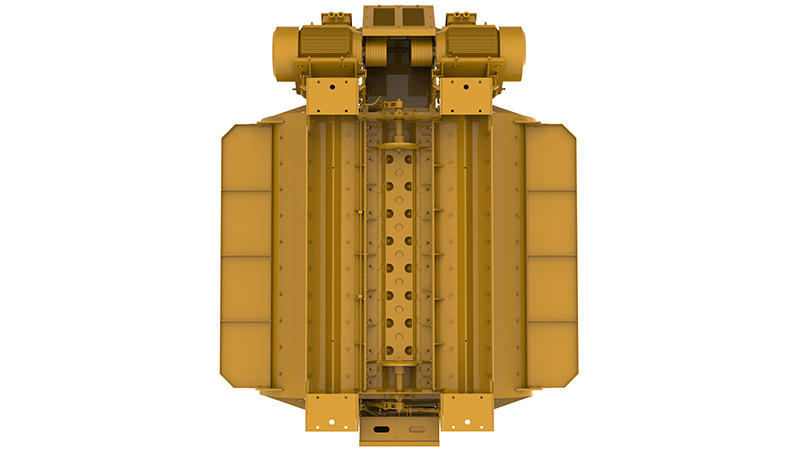

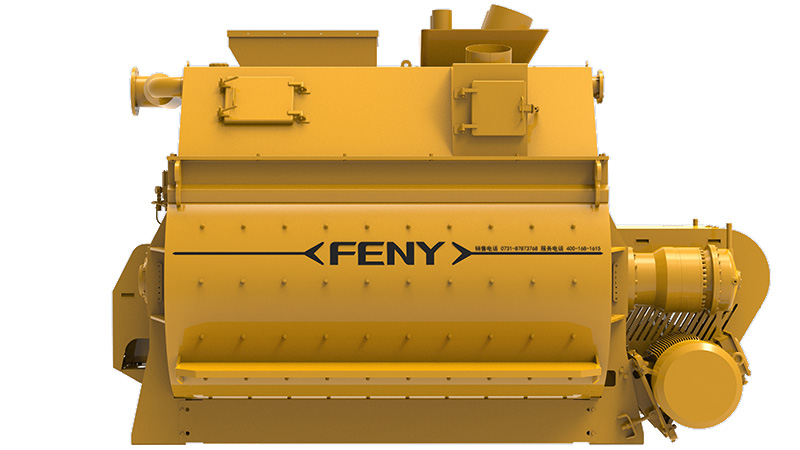

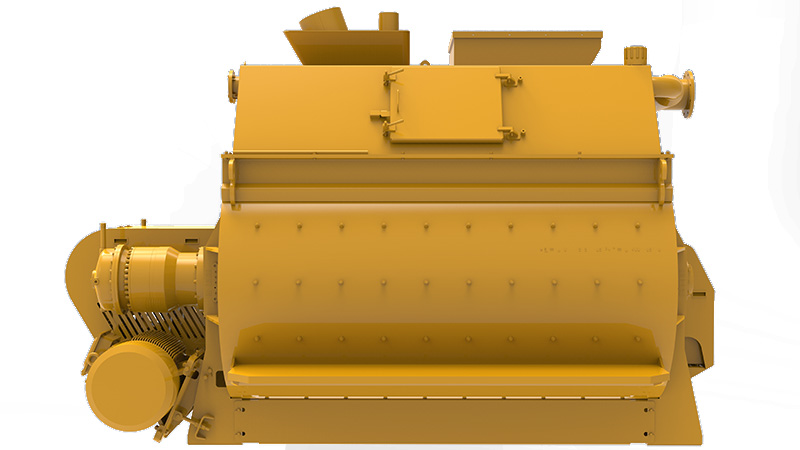

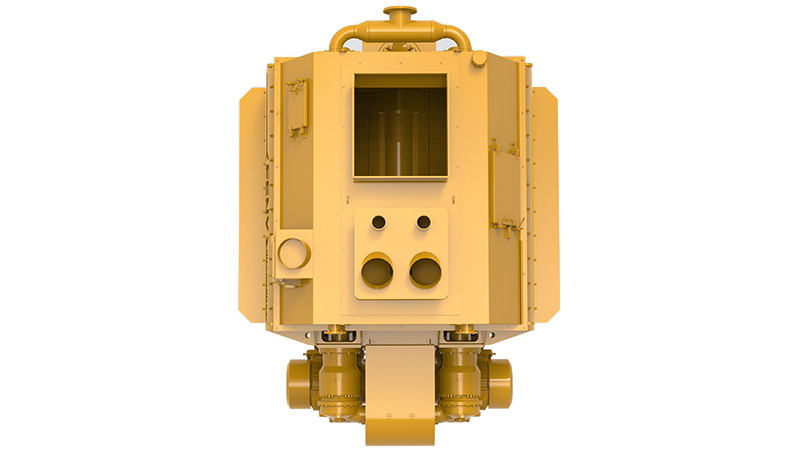

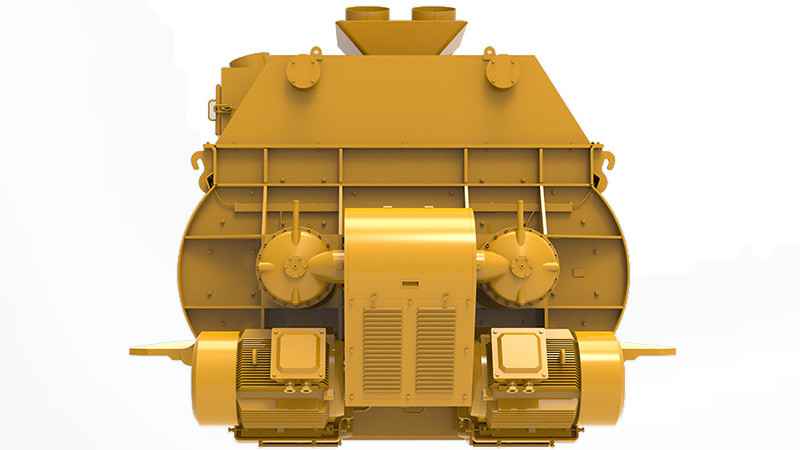

This product is one of the core pieces of equipment in the paste mixing preparation system. The twin-shaft batch mixer offers controllable mixing time and uniform mixing advantages. Its staggered blade design ensures that the mixture is thoroughly, quickly, and evenly blended, significantly improving mixing efficiency. This provides reliable assurance for paste backfill and is mainly suitable for working conditions where coarse aggregate is used as backfill material.

Controllable mixing time thorough mixing.

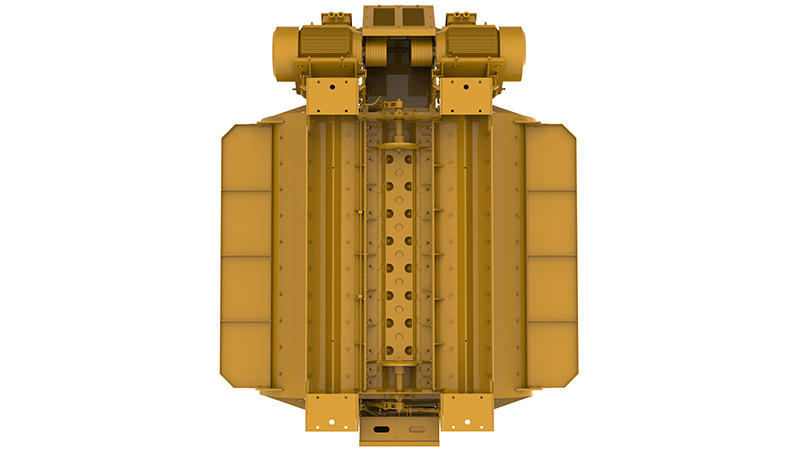

● Thorough Mixing:

The mixing arms and blades are specially designed and arranged to provide excellent mixing results.

● Quantitative Grease Supply:

Equipped with a DC24V fully automatic centralized lubrication system with independent oil pumps at multiple points, ensuring high working pressure with programmable control of operating time.

● High Reliability:

High chromium wear-resistant castings are used, with a service life of over 250,000 m³.

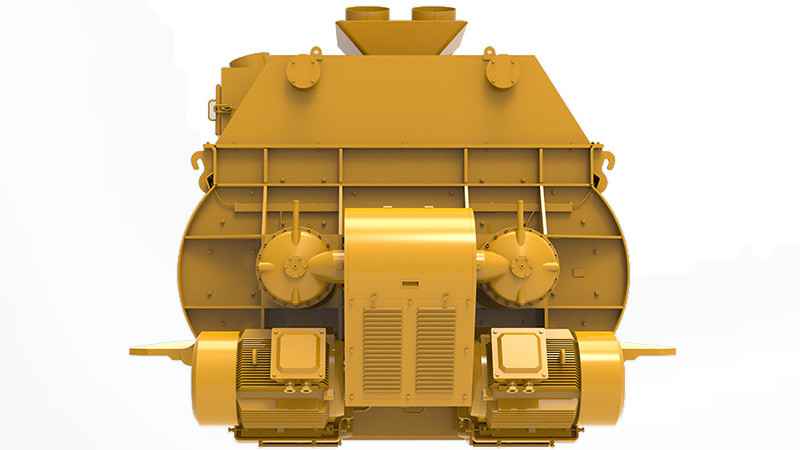

● High Transmission Efficiency:

Equipped with a specialized gearbox for mixers, providing smooth transmission, high efficiency, and high load capacity.

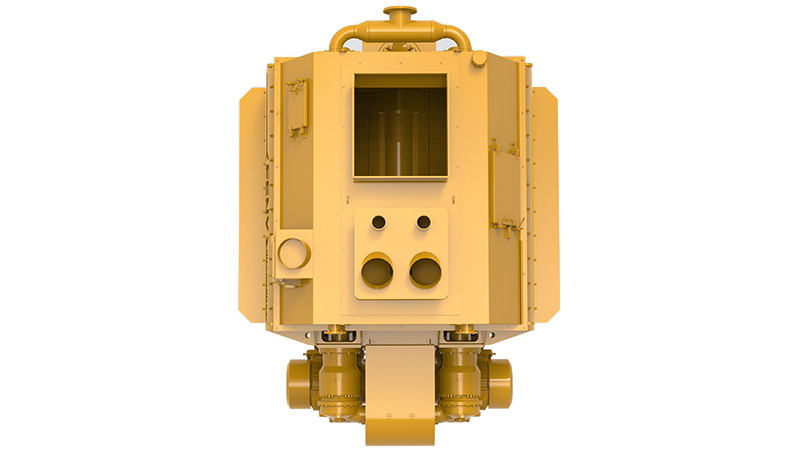

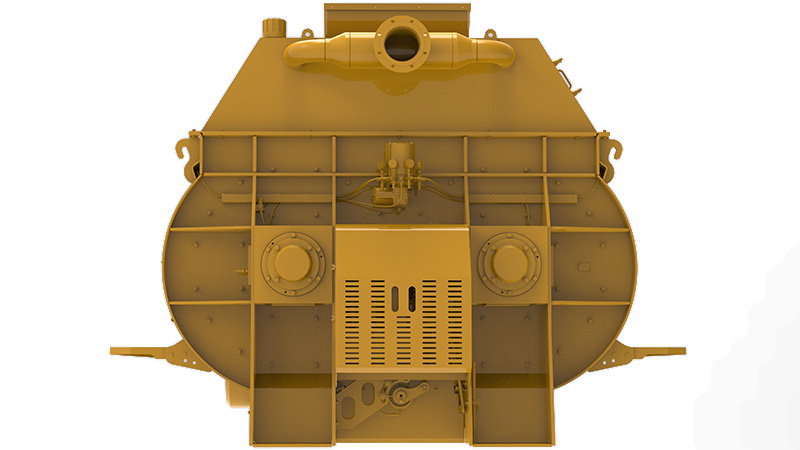

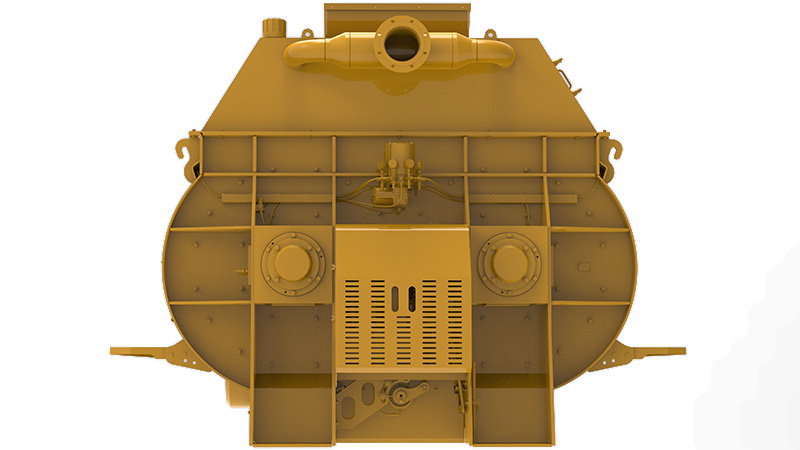

● High Sealing Performance:

The shaft end seal is equipped with a floating oil seal ring and special seals combined with pressure grease to form a multi-layer labyrinth sealing structure,ensuring reliable sealing,high stability,and long service life.

● Easy Maintenance:

Equipped with maintenance platforms or steps, inspection and observation ports feature quick-release locks, ensuring good sealing and easy, quick access for maintenance.

|

Project |

Parameter |

||||

|

Model |

TBM2000 |

TBM3000 |

TBM4000 |

TBM5000 |

TBM6000 |

|

Nominal volume L |

2000 |

3000 |

4000 |

5000 |

6000 |

|

Motor power kW |

2×37 |

2×55 |

2×75 |

2×90 |

2×110 |

|

Dimensions mm |

2590×2470×2040 |

3410×2470×2080 |

3500×2855×2320 |

4260×3180×2760 |

4790×3180×2800 |

|

Maximum aggregate particle size mm |

64 |

64 |

64 |

64 |

64 |

|

Weight kg |

7500 |

10200 |

14000 |

22000 |

24000 |

All of the above manuals apply to standard specifications.

The technical parameters of the customer-specific specifications may deviate from the data in the table above.

All technical parameters will be updated according to the research and development situation, and our company reserves the right to change at any time.

This product is one of the core pieces of equipment in the paste mixing preparation system. The twin-shaft batch mixer offers controllable mixing time and uniform mixing advantages. Its staggered blade design ensures that the mixture is thoroughly, quickly, and evenly blended, significantly improving mixing efficiency. This provides reliable assurance for paste backfill and is mainly suitable for working conditions where coarse aggregate is used as backfill material.

● Thorough Mixing:

The mixing arms and blades are specially designed and arranged to provide excellent mixing results.

● Quantitative Grease Supply:

Equipped with a DC24V fully automatic centralized lubrication system with independent oil pumps at multiple points, ensuring high working pressure with programmable control of operating time.

● High Reliability:

High chromium wear-resistant castings are used, with a service life of over 250,000 m³.

● High Transmission Efficiency:

Equipped with a specialized gearbox for mixers, providing smooth transmission, high efficiency, and high load capacity.

● High Sealing Performance:

The shaft end seal is equipped with a floating oil seal ring and special seals combined with pressure grease to form a multi-layer labyrinth sealing structure,ensuring reliable sealing,high stability,and long service life.

● Easy Maintenance:

Equipped with maintenance platforms or steps, inspection and observation ports feature quick-release locks, ensuring good sealing and easy, quick access for maintenance.

|

Project |

Parameter |

||||

|

Model |

TBM2000 |

TBM3000 |

TBM4000 |

TBM5000 |

TBM6000 |

|

Nominal volume L |

2000 |

3000 |

4000 |

5000 |

6000 |

|

Motor power kW |

2×37 |

2×55 |

2×75 |

2×90 |

2×110 |

|

Dimensions mm |

2590×2470×2040 |

3410×2470×2080 |

3500×2855×2320 |

4260×3180×2760 |

4790×3180×2800 |

|

Maximum aggregate particle size mm |

64 |

64 |

64 |

64 |

64 |

|

Weight kg |

7500 |

10200 |

14000 |

22000 |

24000 |

All of the above manuals apply to standard specifications.

The technical parameters of the customer-specific specifications may deviate from the data in the table above.

All technical parameters will be updated according to the research and development situation, and our company reserves the right to change at any time.

Scan code attention