Tel

86+073187807568

Phone

Phone

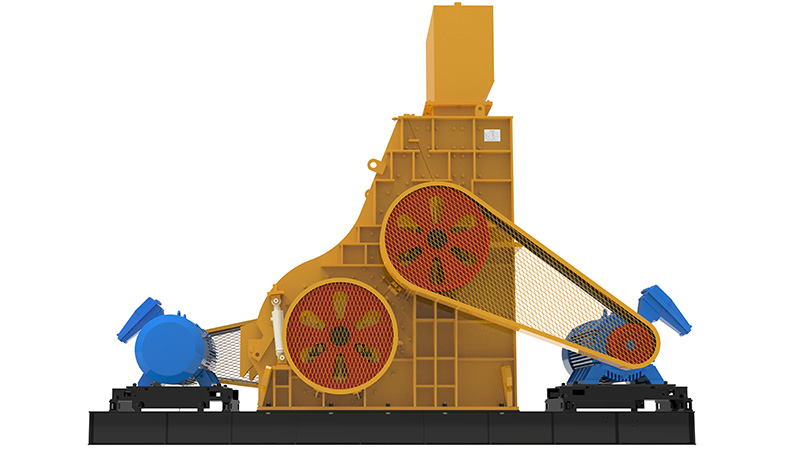

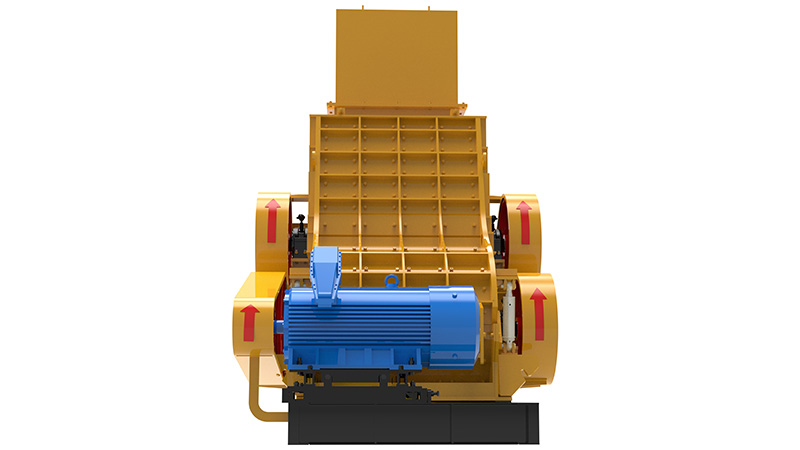

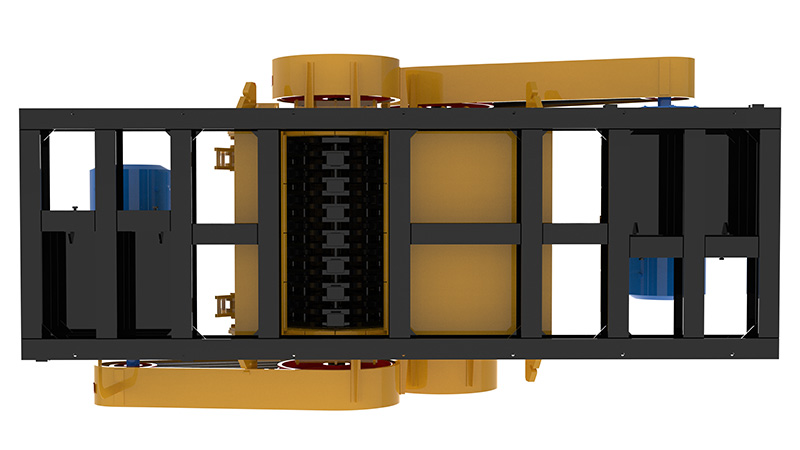

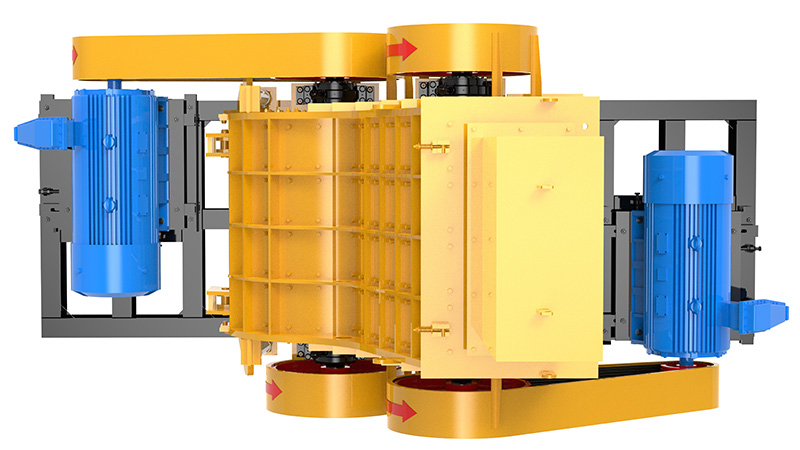

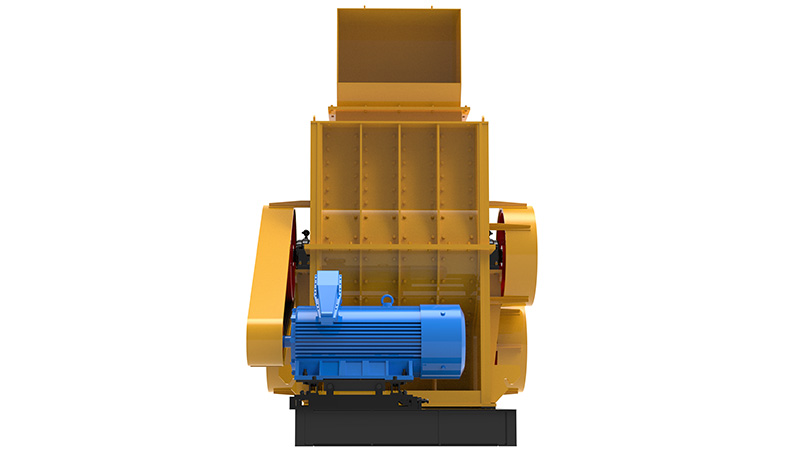

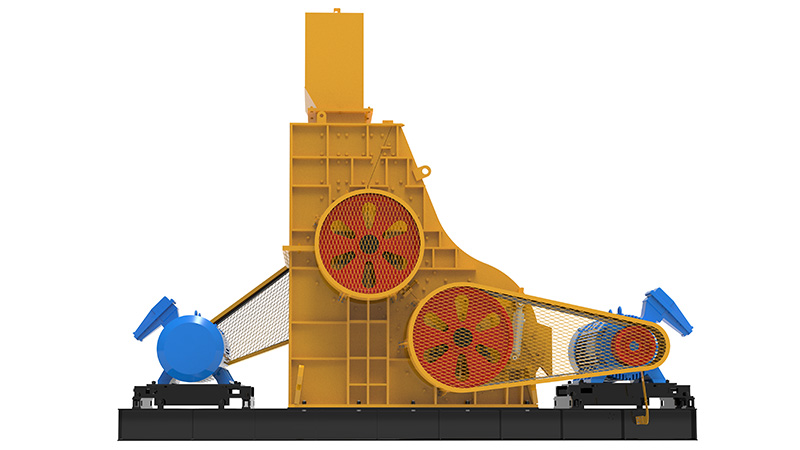

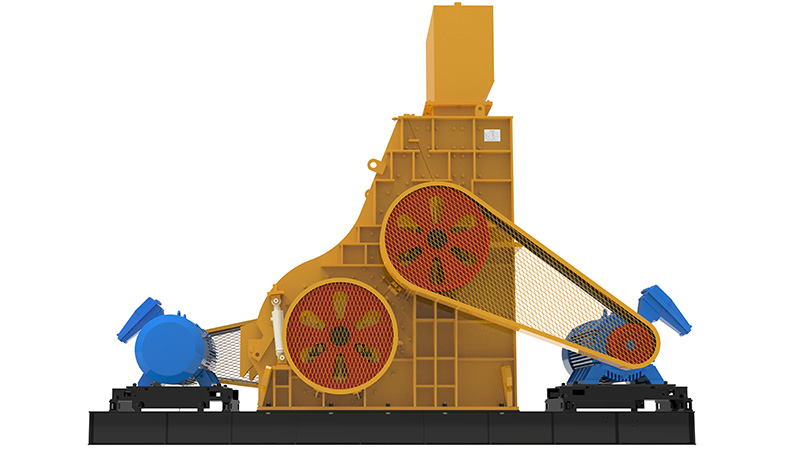

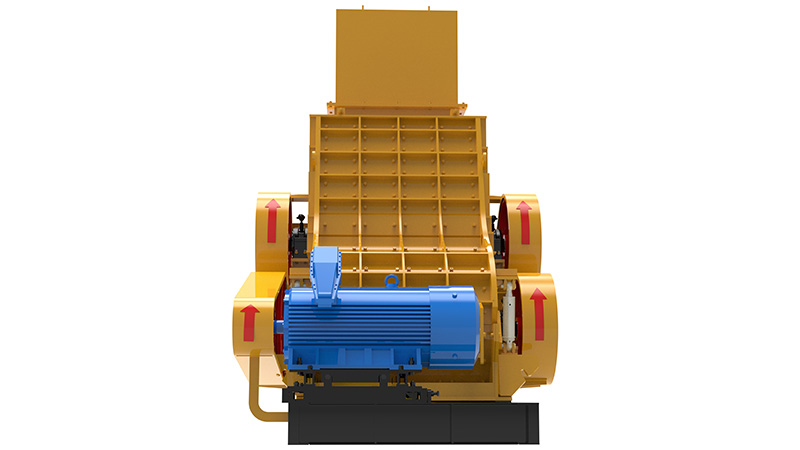

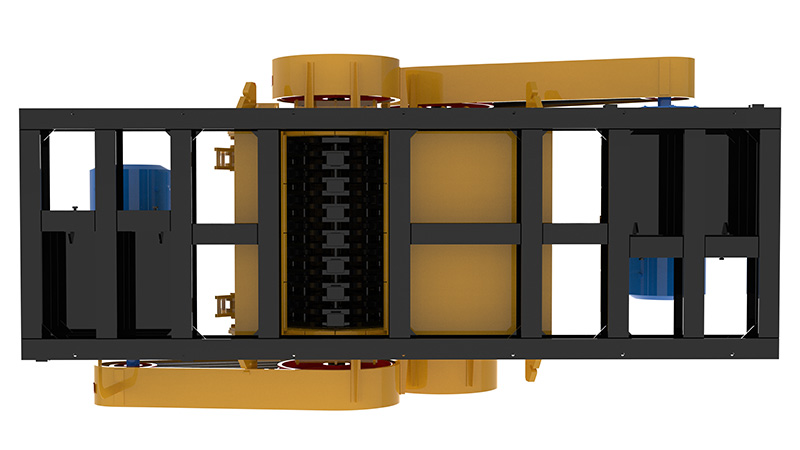

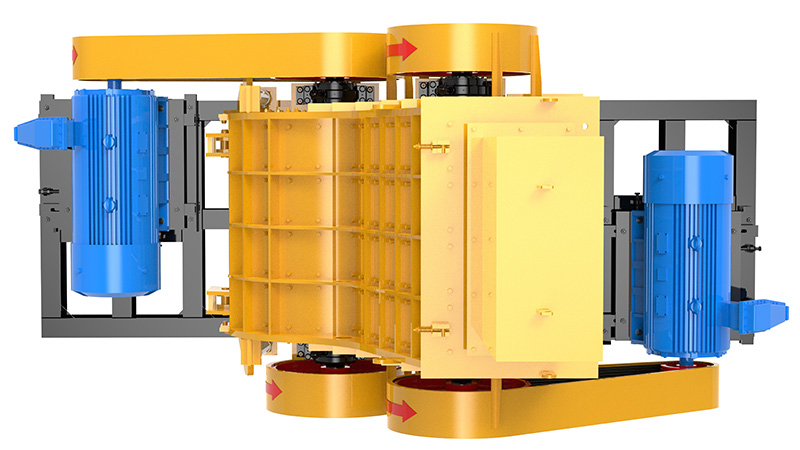

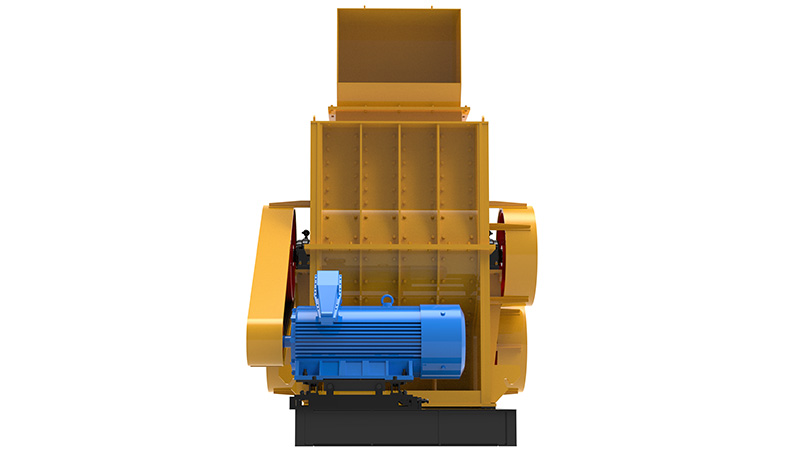

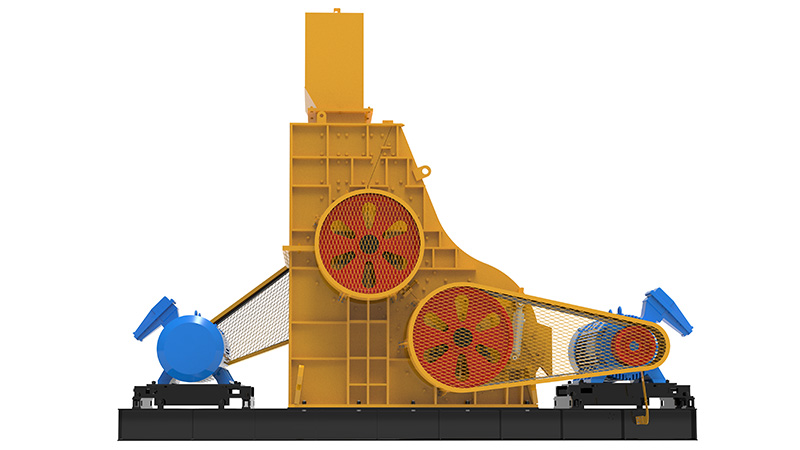

This product is a core piece of equipment in the crushing system, primarily used for crushing coal gangue to ensure that the particle size distribution of the crushed gangue meets the requirements for paste backfill. The equipment operates with two systems inside the chamber, completing the task through two-stage crushing by upper and lower rotors.

No clogging Wear-resistant hammers, and liners.

● Good adaptability

The design without a screen bar ensures that there is no clogging at the

discharge port, making it suitable for materials with a maximum moisture

content of up to 15%.

● High Crushing Ratio and Production Efficiency:

The two systems inside the chamber, with dual-stage crushing from upper and lower rotors, achieve intermediate and fine crushing in a single machine.

● Wear-Resistant, Impact-Resistant, Energy-Saving, and Environmentally Friendly:

Wear parts such as hammers, liners, and rotors are made from various

high-wear-resistant alloy materials, ensuring a long service life. The flywheel

energy storage design provides smooth operation with high inertia, low impact,

and energy savings.

● Stable Operation with Excellent Crushing Effect:

The machine features an aesthetically pleasing design with a compact structure,

allowing for long-term stable operation. It has a high crushing ratio and

produces reasonably graded particle sizes.

● Good Maintainability:

The hydraulic opening and closing shell design allows for easy and quick

replacement and maintenance of parts.

|

Project |

Parameter |

|||

|

Model |

2PC1012 |

2PC1214 |

2PC1416 |

2PC1620 |

|

The moisture content of the material used % |

≤15 |

≤15 |

≤15 |

≤15 |

|

Incoming particle size mm |

≤130 |

≤130 |

≤150 |

≤200 |

|

Discharge particle size mm |

≤10 |

≤10 |

≤10 |

≤10 |

|

Production capacity t/h |

60 |

100 |

150 |

200 |

|

Reference motor powerkW |

2×132 |

2×185 |

2×250 |

2×400 |

All of the above manuals apply to standard specifications.

The technical parameters of the customer-specific specifications may deviate from the data in the table above.

All technical parameters will be updated according to the research and development situation, and our company reserves the right to change at any time.

This product is a core piece of equipment in the crushing system, primarily used for crushing coal gangue to ensure that the particle size distribution of the crushed gangue meets the requirements for paste backfill. The equipment operates with two systems inside the chamber, completing the task through two-stage crushing by upper and lower rotors.

● Good adaptability

The design without a screen bar ensures that there is no clogging at the

discharge port, making it suitable for materials with a maximum moisture

content of up to 15%.

● High Crushing Ratio and Production Efficiency:

The two systems inside the chamber, with dual-stage crushing from upper and lower rotors, achieve intermediate and fine crushing in a single machine.

● Wear-Resistant, Impact-Resistant, Energy-Saving, and Environmentally Friendly:

Wear parts such as hammers, liners, and rotors are made from various

high-wear-resistant alloy materials, ensuring a long service life. The flywheel

energy storage design provides smooth operation with high inertia, low impact,

and energy savings.

● Stable Operation with Excellent Crushing Effect:

The machine features an aesthetically pleasing design with a compact structure,

allowing for long-term stable operation. It has a high crushing ratio and

produces reasonably graded particle sizes.

● Good Maintainability:

The hydraulic opening and closing shell design allows for easy and quick

replacement and maintenance of parts.

|

Project |

Parameter |

|||

|

Model |

2PC1012 |

2PC1214 |

2PC1416 |

2PC1620 |

|

The moisture content of the material used % |

≤15 |

≤15 |

≤15 |

≤15 |

|

Incoming particle size mm |

≤130 |

≤130 |

≤150 |

≤200 |

|

Discharge particle size mm |

≤10 |

≤10 |

≤10 |

≤10 |

|

Production capacity t/h |

60 |

100 |

150 |

200 |

|

Reference motor powerkW |

2×132 |

2×185 |

2×250 |

2×400 |

All of the above manuals apply to standard specifications.

The technical parameters of the customer-specific specifications may deviate from the data in the table above.

All technical parameters will be updated according to the research and development situation, and our company reserves the right to change at any time.

Scan code attention